Auto Splitting Machine

The D-1 supports MES integration for automatic reel-splitting functions while also allowing manual input of material quantities, enabling high-speed, high-precision reel-splitting operations. As an integrated multifunctional device, the D-1 can simultaneously perform component counting functions. Compared to manual operations, it improves reel-splitting and counting efficiency by over 30%, achieves counting accuracy exceeding 99%, and reduces manual labor effort by more than 50%. With a compact design measuring just 1 meter in length, significantly saving warehouse layout space. Combining ease of use with reliability, the D-1 Smart reel-splitting machine empowers lean production with smart hardware.

● Support 8, 12, 16, 24mm component tape width

● Support paper and embossed tape

● Support deep pocket up to 9mm

● Support built counting function

● Optional LCR verification for Capacitors and Resistors

● Optional silk-screen recognition & verification

● Standard smart vision system

● Automatic empty-tape detection

● Tape width & spacing memory function

● Supports label printing

● Support MES customization

TECHNICAL SPECIFICATIONS

|

Information of component tape |

Component tape width (mm) |

8/12/16/24 |

|

Component pitch (mm) |

2/4/8/12/16/20/24 |

|

|

Component pocket depth max. (mm) |

9 |

|

|

Component tape thickness(8mm tape)(mm) |

0.25~1.25 |

|

|

Min. splitting length(mm) |

140 |

|

|

Conveyor system |

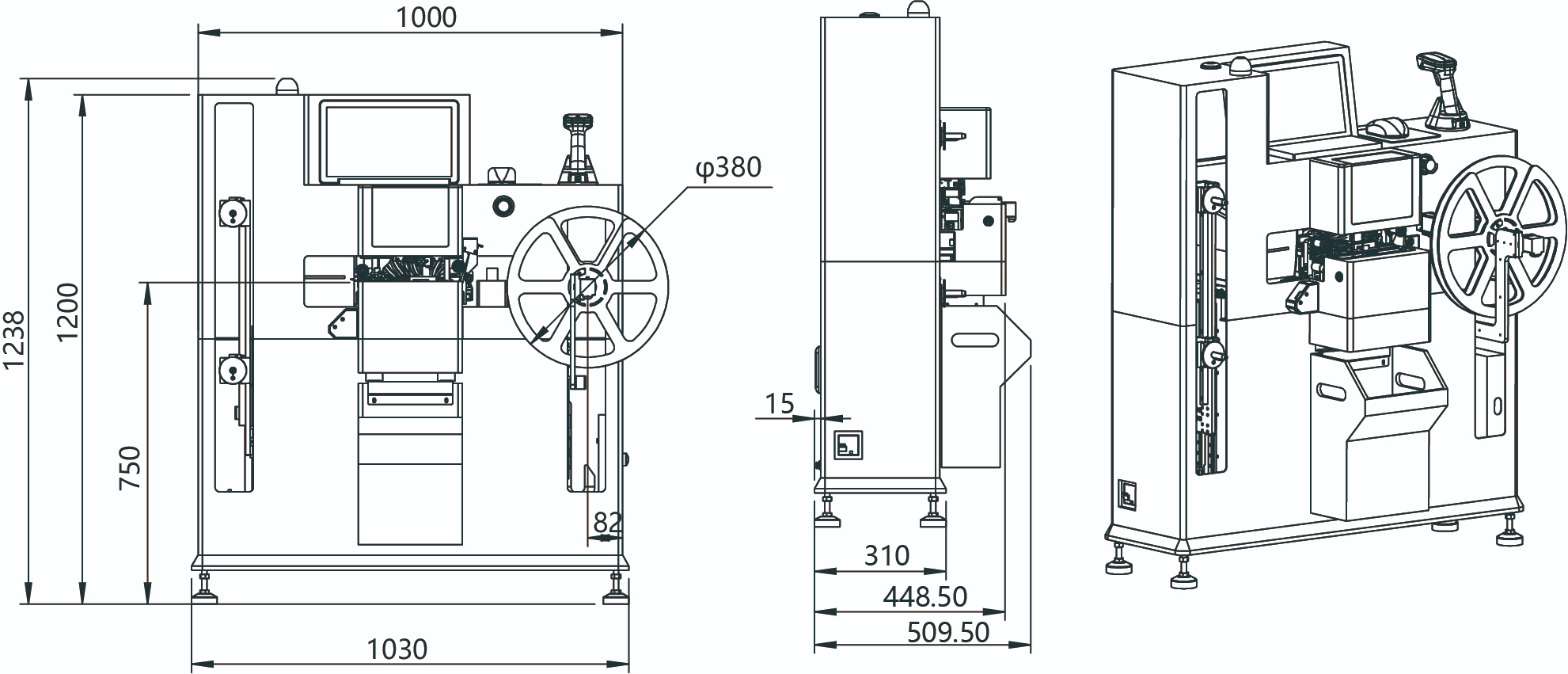

Conveyor height(mm) |

750±15 |

|

Conveyor width |

Auto adjustable rail width |

|

|

Rewinding device |

Rewinding unit |

Dual take-up spindles( height adjustable) |

|

Intermediate tray |

Programmable width & height adjustment |

|

|

Tray dimensions(mm) |

Max.Ø330 |

|

|

Barcode reading |

Barcode scanner |

Optional |

|

Auxiliary functions |

Label printer |

Standard |

|

Tape cutter |

Standard |

|

|

Software control |

Tape width and pitch |

Auto Save |

|

Power |

Power |

220V/Single-phase/50Hz/10A |

|

Air Source |

Air pressure |

0.5Mpa |

|

Facilities Requirements |

Weight (Kgs) |

100 |

|

Reference Dimension(mm) |

510(W) × 1030(L) × 1240(H) |

|

|

Other configurations optional |

MES customization、LCR、OCR |

|

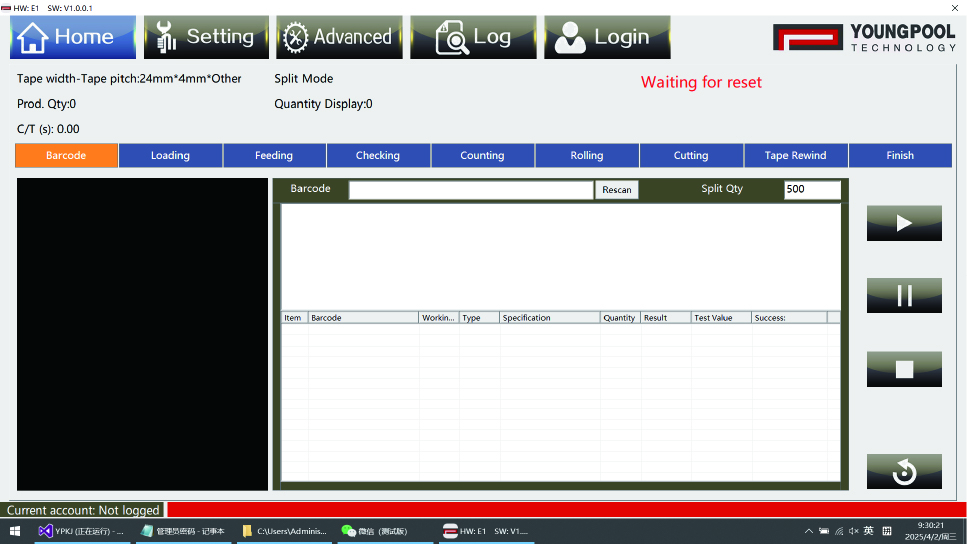

Simple, Intuitive GUI

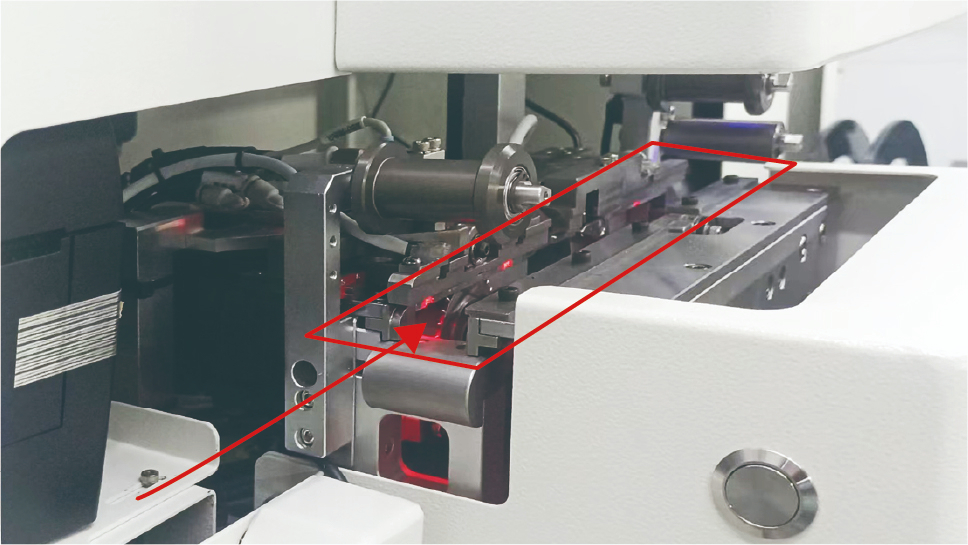

8-24mm Auto-adjustable Rail

Dimensions

IPv6 network supported

IPv6 network supported