Categories

New Blog

Automatic Empty Carrier Detection and Cutting: A Key Step in Maintaining SMT Splicing Continuity

Sep 03, 2025On the SMT production line, the continuity of the carrier tape determines the stability of the line operation. However, the common occurrence of "empty carriers" in actual production often becomes a hidden risk affecting yield. If empty carriers proceed untreated into the pick-and-place machine, it can lead to failed nozzle pickups causing missed placements in minor cases, or result in batch missed placements or defective products moving to subsequent processes in severe cases, increasing rework and costs.

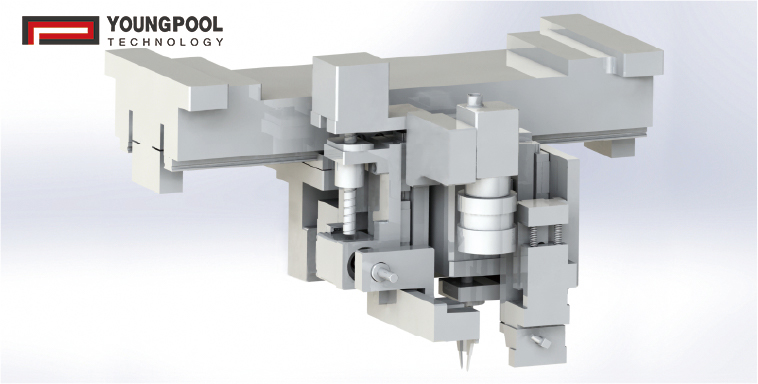

From the initial design stage, Youngpool Technology's SMT automatic splicer has fully considered this issue. The equipment comes standard with automatic empty carrier detection and cutting functionality during the splicing process, ensuring the integrity and continuity of the spliced carrier tape and reducing impact on subsequent placement operations.

The splicer utilizes a combination of sensors and vision systems to perform point-by-point inspection of the carrier tape entering the splicing stage. Once an empty carrier is detected, the system immediately marks it and triggers the automatic cutting process. Compared to traditional manual visual inspection, this feature offers:

- High-speed recognition: Rapid detection response, capable of identifying empty carriers without affecting the splicing cycle;

- Precision and stability: Reduced risk of human oversight and misjudgment;

- Unified standards: Ensures carrier tapes entering the splicing process comply with the same inspection criteria.

It should be noted that this function primarily targets the splicing process and does not perform full-length inspection of entire reel tapes. Therefore, it cannot completely avoid "shortage" issues inherent in upstream materials. However, during the splicing stage, it can promptly remove empty carrier sections, preventing further risk propagation.

Upon detecting empty carriers, the equipment automatically performs cutting, allowing only effective carrier tape to proceed to the splicing stage. The entire process requires no manual intervention, helping the production line achieve:

- Reduced downtime: Prevents interruptions caused by empty carriers entering the pick-and-place machine;

- Improved splicing quality: Lowers the risk of missed placements, maintaining stability of the spliced carrier tape in subsequent placement processes.

The automatic empty carrier detection and cutting functionality not only enhances operational convenience but also creates tangible value in actual production:

- Reduced scrap and rework: Lowers defect rates caused by empty carriers;

- Labor savings: Decreases manual inspections and hand cutting;

- Strengthened quality control: Supports MES systems by enabling data retention and traceability of detection results, helping enterprises enhance process management.

As a crucial element of production line automation, the splicer's empty carrier detection and cutting functionality not only addresses long-standing splicing quality issues but also demonstrates the direction of smart manufacturing:

- Integration with intelligent vision systems to achieve unified detection and processing;

- Interconnection with MES systems, supporting empty carrier data tracking and process monitoring;

- Reduction of manual intervention in large-scale production lines, enhancing stability across the entire production chain.

The SMT industry is evolving into a phase characterized by high speed, high density, and high precision. The standard automatic empty carrier detection and cutting functionality in Youngpool Technology's SMT automatic splicer safeguards the stability of the splicing process and product quality. While it doesn't inspect entire reel tapes, it effectively improves yield and first-pass rates during the splicing process, helping enterprises achieve more efficient and intelligent production. Making splicing no longer a bottleneck represents another practice of Youngpool Technology's philosophy to "make electronics manufacturing simpler."