Categories

New Blog

LCR Testing: Making SMT Splicing Smarter and More Reliable

Aug 27, 2025

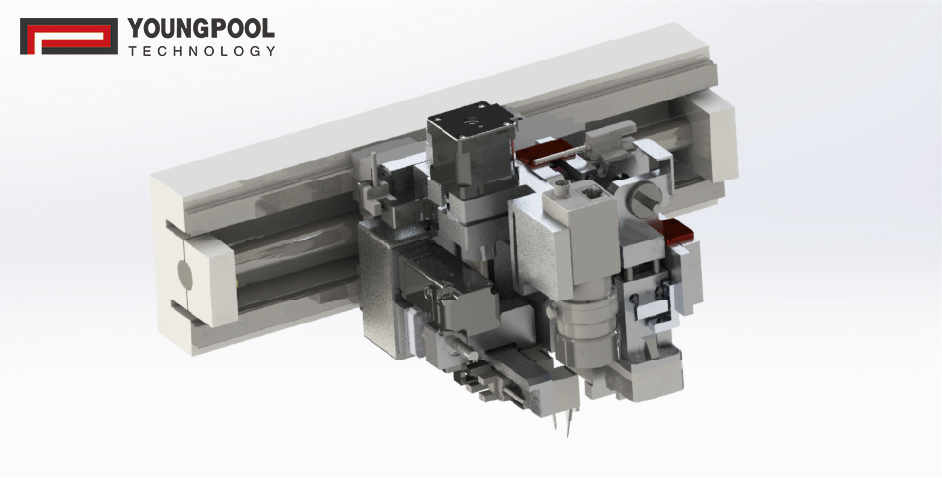

In the electronics manufacturing industry, the quality and consistency of components directly determine product performance and stability. With the increasing miniaturization and complexity of devices, traditional manual sampling or visual inspection alone can no longer meet the stringent quality requirements of high-end manufacturing. Youngpool Technology has introduced LCR testing functionality into its intelligent splicing machines, providing more reliable assurance for SMT production.

What is LCR Testing?

LCR refers to inductance (L), capacitance (C), and resistance (R). In the SMT production process, components often need to be verified during the splicing stage. Youngpool Technology's Automatic splicing machines can be equipped with an LCR testing system, which utilizes an independent X/Y/Z three-axis measurement platform to quickly test the electrical parameters of components.

This means that electrical verification can be achieved during the splicing process, from tiny 01005 components to common large-sized inductors and capacitors.

The Value of LCR Testing

In SMT manufacturing, "material mixing" and "false soldering" are two major pain points on the production line. The introduction of LCR testing effectively addresses these challenges:

1. Preventing Material Mixing

Two resistors or capacitors with similar appearances, if used without verification, can easily lead to the scrapping of an entire batch of products. LCR testing can directly identify and isolate non-compliant materials during the splicing process.

2. Improving Yield

Effectively prevents "defective components" from entering the production process. Through electrical testing, non-compliant components are eliminated before they enter the pick-and-place machine, ensuring every component on the production line meets standards.

3. Reducing Reliance on Manual Labor

Traditional sampling inspections often require manual comparison one by one, which is inefficient and prone to errors. In contrast, LCR automated testing completes the process in seconds, saving labor and improving accuracy.

Integration with MES

Youngpool Technology's intelligent splicing machines not only feature testing capabilities but also support integration with MES systems. LCR test results can be uploaded in real time, forming a complete data traceability chain. This means customers can use MES to:

Future-Oriented Quality Assurance

As electronics manufacturing moves toward higher density and reliability, the era of relying solely on manual experience is over. The application of LCR testing transforms splicing from mere "material connection" into an intelligent process with testing, error prevention, and traceability capabilities.

Youngpool Technology's introduction of this functionality into SMT splicing machines is not only a reflection of technological advancement but also a comprehensive guarantee of production quality for customers. It represents a shift in SMT manufacturing from "efficiency-driven" to "quality-driven" and is an essential component of future smart factory construction.

In the highly competitive SMT industry, high efficiency + high yield is the core competitiveness. The LCR testing functionality of Youngpool Technology's intelligent splicing machines is a key enabler in achieving this goal. By "moving testing forward," potential risks are stopped before they enter the production line, helping customers truly achieve—smarter splicing and more reliable quality.