Categories

New Blog

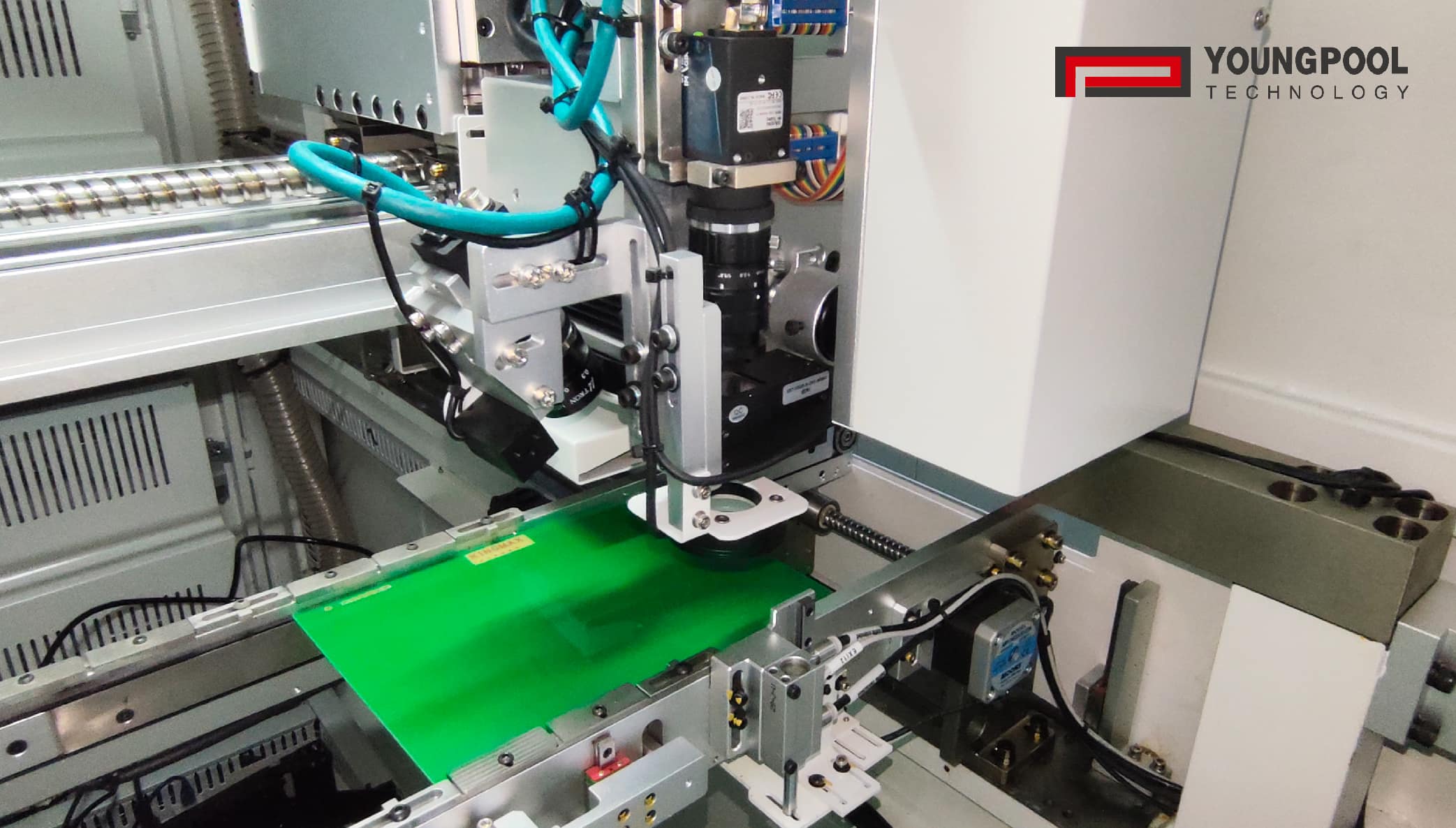

Complete Operation Guide for Youngpool Technology Laser Marking Machine

May 28, 2025

Basic Equipment Operation Procedures

Power-On Preparation Phase

Check optical lens cleanliness

Verify air supply is normal

Perform cooling system self-test before startup

Workpiece Positioning Setup

Use CCD vision for automatic alignment

Manually fine-tune positioning reference points

Establish workpiece coordinate system

Marking Program Creation

Parameter Configuration

Select laser wavelength based on material

Set power/frequency/speed parameter combinations

Configure marking depth compensation

Content Design

Import vector graphic files

Set automatic serial number increment rules

Establish QR code data association

Production Operation

Batch Processing Mode

Set automatic continuous processing parameters

Configure automatic material number recognition

Enable automatic rejection of defective products

Quality Monitoring

Real-time QR code readability detection

Automatic recording of marking position deviations

Generate process capability reports

Routine Maintenance Points

Optical System Maintenance

Daily lens cleaning procedures

Monthly optical path calibration

Quarterly galvanometer maintenance

Key Component Inspection

Guide rail lubrication cycle management

Laser operating status monitoring

Cooling system efficiency testing

Intelligent Function Applications

MES System Integration

Automatic production data upload

Cloud-based process parameter calling

Remote equipment status monitoring

Exception Handling

Automatic alarm classification processing

Adaptive adjustment of process parameters

Fault self-diagnosis function

This equipment features a user-friendly interface, allowing basic operations to be mastered through short-term training while also providing in-depth support for advanced functions to meet the process requirements of users at different levels.