Categories

New Blog

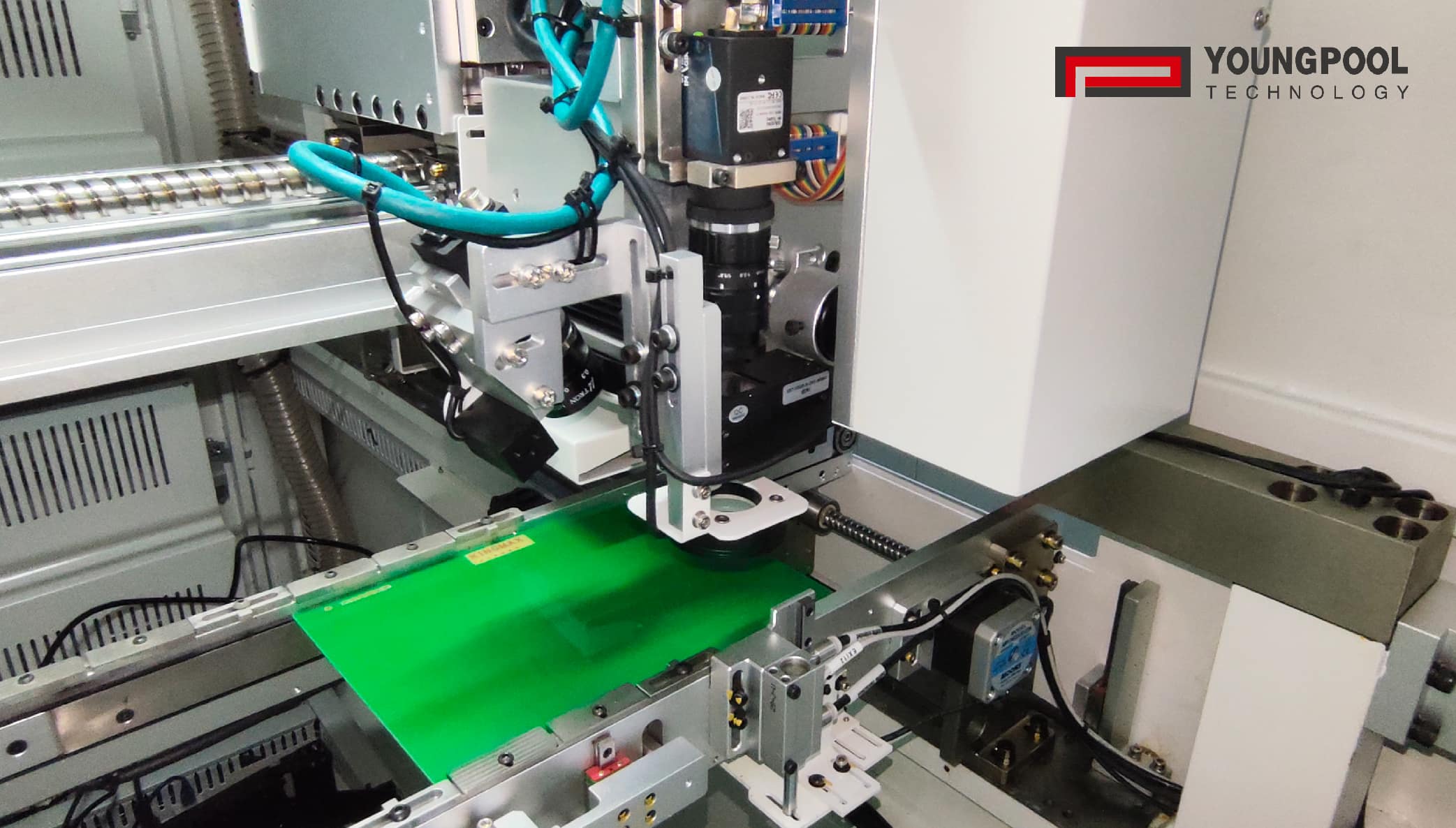

Core Application Value of Youngpool Technology Laser Marking Machines in Electronics Manufacturing

May 28, 2025

Core Application Value of Youngpool Technology Laser Marking Machines in Electronics Manufacturing

In the field of precision electronics manufacturing, Youngpool Technology laser marking machines have become indispensable process equipment for SMT production lines due to their specialized design. Unlike generic laser equipment, our systems are deeply optimized for the special requirements of electronics manufacturing.

Core Functions of Precision Marking

Product Lifecycle Traceability

UDI (Unique Device Identification) marking for medical electronic devices

Automotive-grade weather-resistant traceability codes

Component-level tracking with high-density QR codes

Process Control Markings

Solder paste printing alignment marks

Panel alignment reference points

AOI (Automated Optical Inspection) positioning marks

Industry-Specific Application Scenarios

Aerospace Electronics

Permanent part numbering on high-temperature substrates

Tamper-evident security markings

Military-standard compliant markings

Automotive Electronics

VIN-based component traceability

Engine compartment component identification

Vibration-resistant durable markings

Medical Device Manufacturing

UDI-compliant direct part marking

Biocompatible material engraving

Micro-scale marking for implantable devices

Special Material Processing Capabilities

Beyond standard FR4 substrates, our equipment excels at:

Crack-free marking on ceramic circuits

Deformation-free engraving on flexible PCBs

RF component identification without affecting signal integrity

Smart Manufacturing Integration Advantages

The core value of the equipment is reflected in its seamless integration with:

Smart factory IoT systems

Automated material handling systems

Real-time quality monitoring platforms

Youngpool Technology laser marking machines address unique challenges in electronics manufacturing, including the durability of marks after multiple reflow soldering processes and micron-level precision marking for miniature components. They are essential process equipment for advancing PCB technology boundaries.