Categories

New Blog

The Practical Value of LCR Measurement Error-Proofing in the Splicing Process

Sep 23, 2025

On an SMT production line, splicing is often regarded as a basic material-handling action, yet in reality, it has a direct impact on line continuity and final yield. If quality control can be introduced at this stage, many potential issues can be eliminated at the source, preventing them from being amplified in subsequent processes.

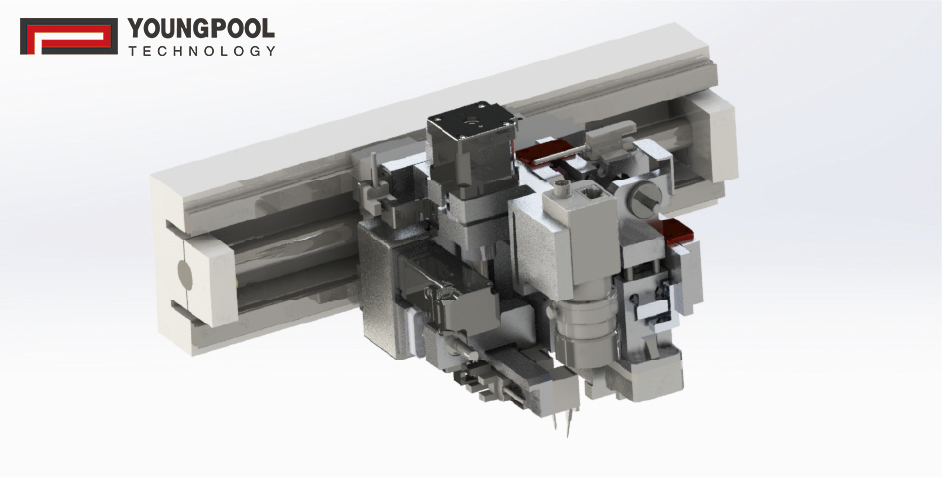

Youngpool Technology’s automatic splicing machine is designed with this concept in mind. In addition to efficient automatic splicing and reel replacement, it can be optionally equipped with an LCR measurement module to perform rapid electrical parameter testing on passive components such as resistors, capacitors, and inductors. By conducting first-article verification, random checks during reel changes, or exception sampling at the splicing stage, nonconforming components can be intercepted before entering production, thereby reducing the risk of large-scale rework or line downtime. In practice, splicing is typically achieved through “carrier tape joining,” where splicing tape is used to precisely connect the old and new carrier tapes.

The value of this detection method lies not only in intercepting incorrect materials but also in its ability to integrate with barcode traceability, intelligent vision, and MES systems, forming a complete data chain: detection, recording, reporting, and traceability. This enables faster problem localization and provides a solid basis for subsequent improvements. However, integration with MES or vision systems requires field and protocol alignment during project implementation to achieve a true closed loop.

For manufacturing enterprises, the introduction of LCR measurement transforms splicing from a mere “material connection” into a quality checkpoint. It not only improves first-pass yield but also ensures more stable delivery. Combined with automated splicing capability, enterprises can shift quality assurance upstream without compromising production efficiency, minimizing potential losses caused by material errors.

In summary, LCR measurement error-proofing is not a standalone quality assurance method, but rather a critical part of a multi-layered error-proofing system. Through collaboration with barcode systems, vision inspection, and downstream testing, it can deliver real value on SMT production lines. For companies pursuing high yield and stable delivery, this seemingly minor step often brings unexpected benefits.