Categories

New Blog

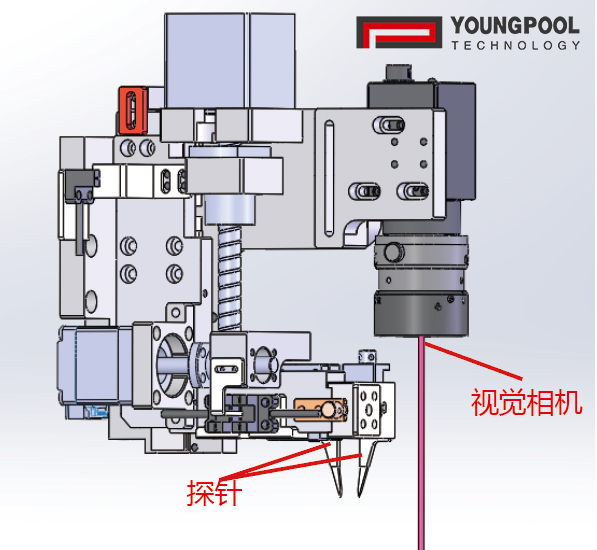

Variable-Pitch Measurement Mechanism Enables 01005 Component Testing, Enhancing SMT Line Adaptability

Sep 25, 2025

As electronic products continue to evolve toward miniaturization and higher density, the adoption of 01005 components (0.4 mm × 0.2 mm) has become increasingly widespread. While these ultra-miniature devices improve circuit design compactness, they also impose extremely stringent requirements on production testing. Traditional measurement mechanisms with fixed probes often struggle to achieve reliable contact with such tiny pads. The Youngpool Technology L-900 Auto Splicing Machine incorporates a variable-pitch measurement mechanism in its design, providing a new solution for micro-component testing on SMT production lines.

The core advantage of the variable-pitch structure lies in its flexibility. By adjusting probe positions and spacing, the system can accommodate multiple package sizes, reducing fixture replacement in most scenarios, thereby shortening changeover time and improving line efficiency. This flexibility is particularly critical in high-mix, low-volume production models. However, when dealing with ultra-micro components such as 01005, dedicated low-force micro-probes and recalibration procedures are still required to ensure stable contact and accurate measurement.

For measurements at the 01005 level, probe contact force control and positioning accuracy are decisive factors. Excessive pressure may damage the component, while insufficient force can lead to false readings. The variable-pitch design, combined with an independent X/Y/Z-axis motion system, helps maintain consistency between probe and electrode contact. At the same time, long-term reliability also depends on proper force-control parameter settings, vibration-damping design, and environmental stability.

The versatility of the variable-pitch structure extends beyond micro-components to conventional resistors, capacitors, and larger packages. By adjusting probe spacing, a single system can address measurement needs across different carrier tapes, thereby reducing both equipment investment and maintenance costs. Nevertheless, when spanning a wide range of package sizes, additional measures such as fixture parasitic compensation, electrical decoupling, and optimized test programs are required to ensure measurement accuracy across parameters ranging from pF-level capacitors to mF-level capacitors.

Overall, the variable-pitch measurement mechanism is not a “universal cure,” but it significantly enhances the L-900’s adaptability across package types, enabling broader application coverage. For SMT lines already handling ultra-small components such as 01005, this design provides a solid technological foundation for automated testing. It elevates the splicing machine from a mere material-connection device to an intelligent node capable of precision screening at the source, supporting yield control and flexible manufacturing strategies for enterprises.