Youngpool Technology LD-4 Inline Laser PCB Depaneling Machine | Enabling Flexible PCB Depaneling for SMT Production Lines

Jan 22, 2026

As electronic manufacturing continues to evolve toward higher density and miniaturization, PCB depaneling has become a critical process affecting both quality and efficiency in SMT production lines. Particularly in consumer electronics, communications, and high-reliability applications, PCB designs are increasingly thinner and lighter, with growing adoption of boards below 0.8 mm in thickness. This trend places higher demands on precision control, stress management, and process consistency during depaneling, driving the technology toward more advanced process solutions.

Limitations of Traditional Depaneling Methods

From the perspective of current SMT industry applications, mechanical router depaneling is still widely used in the market. This is closely related to PCB structural characteristics: for a large number of standard boards with thicknesses above 1 mm, router depaneling remains advantageous in terms of process maturity, processing cost, and applicability, and is also more readily accepted by existing production lines. However, as PCBs continue to move toward thinner, lighter, and higher-density designs, the limitations of mechanically contact-based router depaneling are becoming increasingly apparent. Mechanical stress generated during depaneling, dust contamination, and edge consistency variations caused by tool wear are gradually emerging as potential factors affecting SMT line yield and long-term reliability.

Youngpool Technology Flexible Depaneling Solution

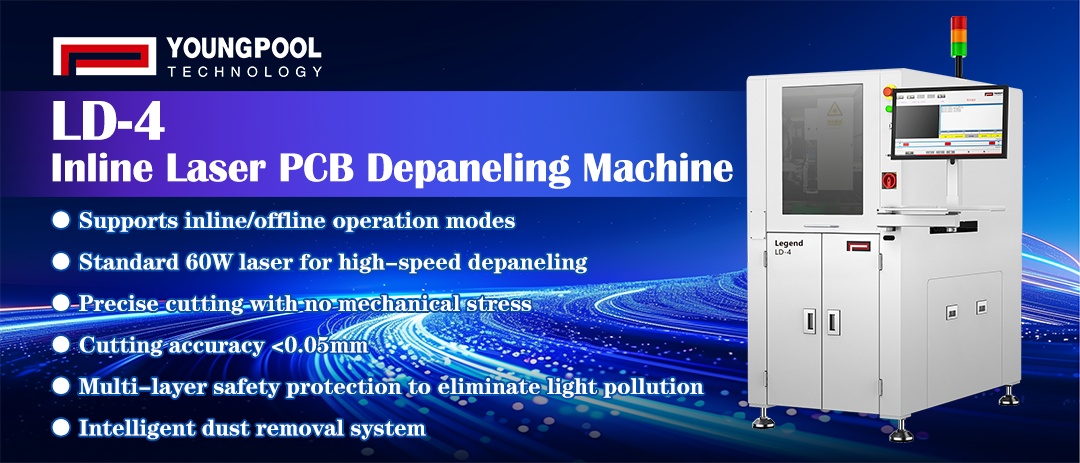

Against this process background, Youngpool Technology has independently developed the LD-4 Inline Laser PCB Depaneling Machine. Utilizing non-contact laser cutting technology, the system is specifically designed to address the depaneling requirements of thin, high-precision, and low-stress PCBs. It is suitable for products with stringent requirements for solder joint reliability, edge quality, and consistency, such as ultra-thin consumer electronics, precision electronic modules, and certain high-end products. For these applications, depaneling is no longer simply about “separating the board,” but about completing the process in a stable, controllable, and high-quality manner without compromising solder joints or component integrity.

Application Value of the Youngpool Technology LD-4 Inline Laser PCB Depaneling Machine

The LD-4 Inline Laser PCB Depaneling Machine is equipped as standard with a 60W green laser source. During depaneling, no mechanical contact is required, effectively minimizing the impact of mechanical stress on solder joints, components, and circuit traces. Combined with galvanometer scanning and graphical programming capabilities, the system can efficiently handle complex depaneling contours while maintaining cutting accuracy within 0.05 mm. An intelligent dust extraction system effectively removes debris generated during the depaneling process, preventing contamination of optical components and ensuring production line quality. Its compact mechanical design and multiple safety protection features also facilitate seamless integration into existing production lines, enabling process upgrades without additional space requirements or management burden.

In terms of application flexibility, the LD-4 Inline Laser PCB Depaneling Machine supports both inline and offline operating modes. For factories with stable output and clearly defined takt times, the inline mode allows direct integration with SMT production lines, ensuring smooth handoff between upstream and downstream processes. For high-mix, low-volume production environments, the offline mode provides greater flexibility without disrupting the main production line rhythm. This dual-mode design enables the LD-4 to meet the needs of customers with different production scales and organizational models.

The core value of the LD-4 Inline Laser PCB Depaneling Machine lies in its ability to enhance production line stability and product consistency. Rather than simply pursuing the “replacement of traditional processes,” Youngpool Technology addresses the challenges of thinning, precision, and reliability in PCB depaneling within modern electronic manufacturing by offering a more controllable and flexible intelligent solution for specific products and customer segments. By introducing laser technology into the depaneling process, Youngpool Technology aims to help customers further strengthen manufacturing stability throughout product upgrades and process evolution, providing robust support for the consistent delivery of high-quality electronic products.