Categories

New Blog

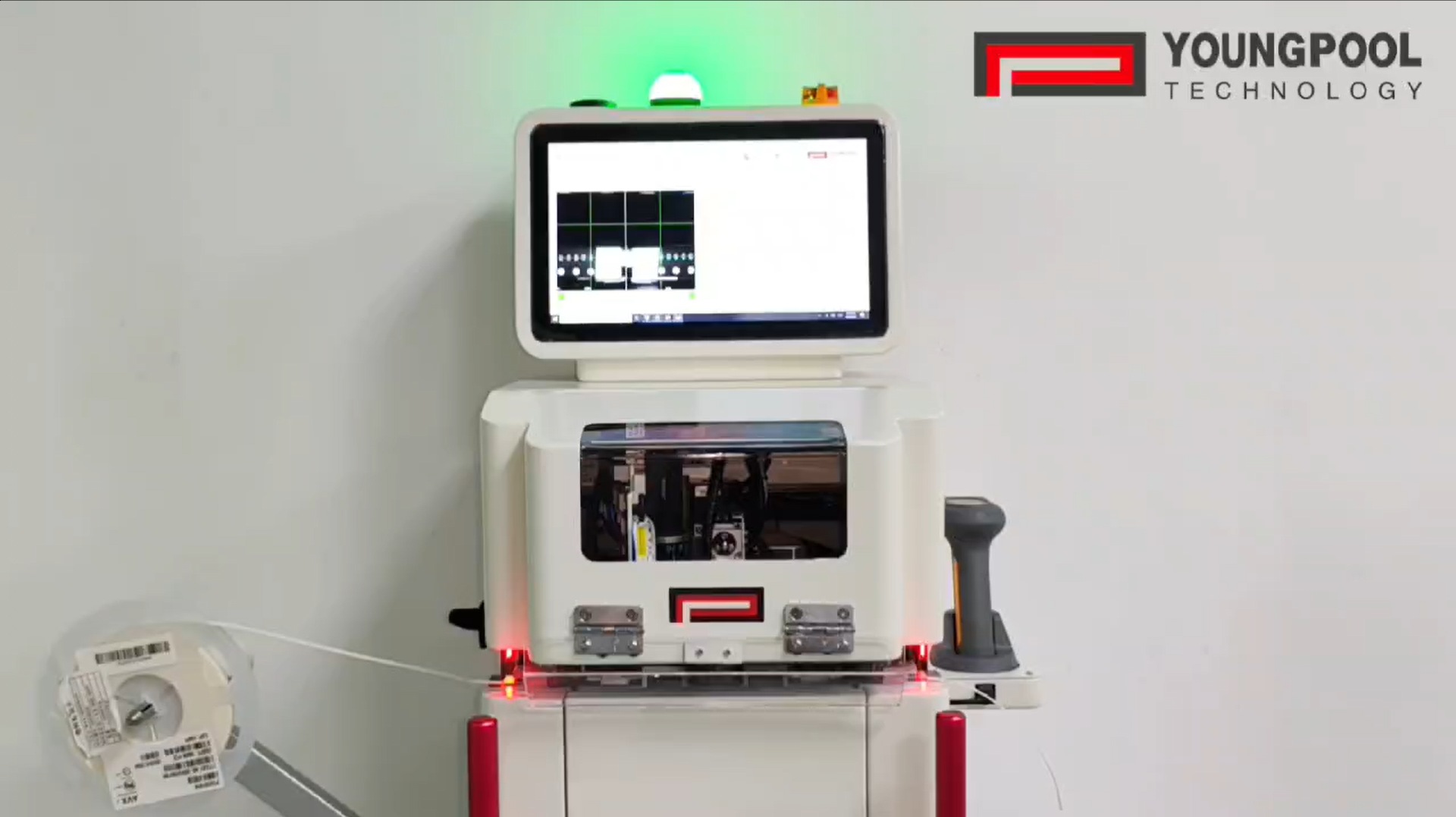

Youngpool Technology L-900 Auto Splicing Machine: One Machine Compatible with the Full Range of 8/12/16/24 mm Tape Widths

Jan 07, 2026

In SMT production lines, high-mix, low-volume manufacturing has become the norm. The continuity and stability of material replenishment directly affect overall line efficiency and equipment utilization. As a key auxiliary device in SMT lines, the primary function of a splicing machine is to achieve precise tape splicing through standardized and automated processes, thereby minimizing the impact of human factors on splice quality and production takt time.

Traditional manual splicing relies heavily on operator experience. Under conditions of frequent material replenishment and continuous operation, it is difficult to ensure consistency of splice positioning and stability of splicing quality, which can easily lead to process abnormalities such as component throwing and tape jamming during subsequent placement operations.

To address these industry pain points, Youngpool Technology has independently developed and launched the L-900 Auto Splicing Machine. The equipment features an original variable-rail mechanism design, enabling a single machine to be compatible with mainstream tape widths of 8 mm, 12 mm, 16 mm, and 24 mm. Operators only need to select the tape width and feed pitch parameters on the interface; the internal guide rail system and cutting unit automatically and synchronously adjust to complete precise splicing of multiple tape specifications. In addition, the L-900 Auto Splicing Machine supports both paper tapes and plastic carrier tapes, fully accommodating the production requirements of components in different packaging formats and ensuring excellent process compatibility when integrated into existing SMT lines. This structural-level compatibility solution effectively avoids frequent manual intervention caused by differences in material specifications, providing long-term stability for splicing operations.

Overall, the core value of auto splicing machines lies not only in labor substitution, but more importantly in significantly reducing the impact of the splicing process on line efficiency through systematic structural optimization and process reengineering. In the product design of the L-900, Youngpool Technology has continuously enhanced multi-specification compatibility, enabling stable operation in complex material environments and providing SMT production lines with a continuous and reliable auto splicing solution.

For further information, please feel free to contact us:

Email: shicx@youngpool.com

Tel: +86 181 2417 2940